When you want real control

The ECS System is our central modular platform for digital production. Great for process control, production monitoring and production data analysis. Thanks to its modularity and scalability, it is suitable for virtually every industry and production size. Due to the possibility of gradual implementation and development of the system, you can achieve a quick return on your investment without the need for high initial acquisition costs.

Process control of production

Our system is ready for advanced process control of batch production according to ISA S88 standard, offering you extensive possibilities for user adjustments of production processes without the need for programmer intervention.

Complete electronic production records

Treat yourself to a complete electronic production record in the form of measurement waveforms, production logs, actuator statuses, operator interventions, and other data, including laboratory records. Data traceability ensures control over production, maintaining the highest quality, and reducing losses.

Production overview

Choose from a range of clear and detailed production reports and have the system alert users by email or SMS when thresholds are exceeded. Reports available in the web browser and on mobile devices make your decision-making and production planning faster and easier.

Analysis of production and operational data

We automate your existing manual review of production data, saving your staff time that can be spent addressing corrective actions and improving your production efficiency. At the same time, our system will help you to diagnose in detail the causes of deviations from the set standards.

Quality management

We can help you implement digital quality control of your products, raw materials, and sanitation processes. We track the complete flow of raw materials and products to achieve full traceability of production. With tools like SPC, we can help you ensure the continuous stability of key quality parameters of your products.

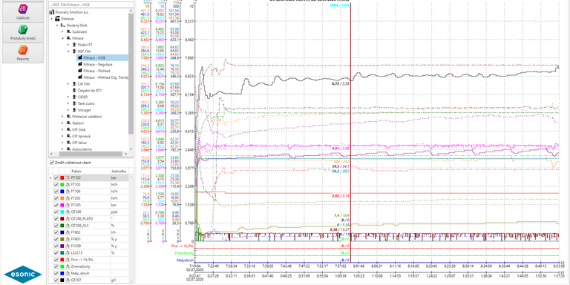

Signal routing

If you need to diagnose very fast processes and signals, for example, from your production machines and cranes, use our ECS Trace tool, which is able to monitor and automatically diagnose signals with a period of less than 100 ms. We’ll help you prevent unplanned downtime and speed up the maintenance of your equipment.

Industry solutions

Thanks to its versatility, the possibilities of ECS applications are almost limitless. The system can also be easily customised and integrated, so you don’t have to worry about complexities. Which fields and solutions are most often encountered in the application of ECS?

– Breweries of all sizes

– Sanitation stations

– Processing and production of bulk materials

– Chemical and pharmaceutical industry

– Process data acquisition and reporting

– Production data analysis

– Automated production quality control

– Energy management

– OEE, analysis of downtime and production outages