When to start automating?

If you are deciding to implement automation in beer production, there are basic questions to consider and answer.

Do you expect the output to increase?

Automation is worthwhile if you plan output higher than about 1.5 thousand hl per year.

Do you have a shortage of skilled workers?

A smart system replaces manpower and decreases HR costs.

Do you want to increase or maintain quality?

Precise processes and recipes will take your brewery to the next level.

Even small breweries deserve cutting-edge technology

Craft beer production has experienced an upward trend in recent years. That’s why we decided to give all smaller breweries our know-how from the world’s great breweries and developed an automation platform tailored to small and medium-sized breweries. It will perfectly compensate for a potential labour shortage and prepare for a higher standard of production.

What will automation bring you?

Repeatability and flexibility

Automation will provide you with a tool that ensures repeatability of production with the same quality, while also having the flexibility to produce different beer styles throughout the day with minimal effort.

Overview

The digital interface provides remote monitoring of the production process, even from mobile devices and perfect reporting from all stages of production.

Performance

Without the need for a permanent physical presence of the brewer and reduced pressure on staff, it will bring more output to your brewery.

Savings

The synergy of the benefits of automation and better overview will allow you to save resources and energy that you can devote to development.

Do you want more? Introducing ESONIC Craft Brewing

Our mission is to help all brewers brew great beer. After several years of development, we, therefore, bring to the segment of small and medium-sized breweries a comprehensive platform for the complete management of beer production, which uses some of the principles of large-scale production.

What is ESONIC Craft Brewing?

It is our standardized solution for the automation of smaller and larger craft breweries. It is based on the SIEMENS Simatic S7-1500 PLC and controlled by our own ESONIC ECS process system.

Central system

Automate your production easily and record data from the entire brewery.

Two main modes

Switch between fully-automatic and semi-automatic mode.

Ready-made software

Choose proven functions and algorithms for process control.

Complete control

Access the record of production progress, including user reports and manual data logging.

Flexible recipe management

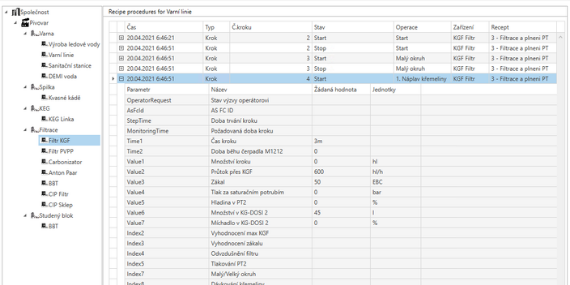

With ESONIC Craft Brewing you are in complete control of recipes. The entire platform of the ECS Batch module, which we developed ourselves, is based on the international ANSI/ISA-88 standard. In practice, this means that you will be able to define new and manage existing production recipes to fine-tune the perfect taste of the final product. If you are interested in data, the system provides you with a record of all production materials and a complete overview of production, including the use of materials in individual batches or semi-finished products. In addition, the results of laboratory tests and analyses at individual stages of production can be entered for batches.

Simple administration

Change only recipes and parameters, not the entire application software.

Ready-made operations

Control individual devices through custom operations, modes, and parameters.

Traceability and control

Oversee production at every step of the production process.

Space for creativity

Discover completely new beer styles with more space for safe experimentation and flavour tuning.

Advanced quality control features

When developing ESONIC Craft Brewing, our main focus was to make the platform as easy to use as possible, fit the various specifics of craft and small brewing, and easy to maintain. But that doesn’t mean we haven’t added features and algorithms that even the biggest breweries use.

Advanced Sanitation

Ensure the process is followed correctly and record progress.

Easier filtration

Choose from different levels of automation – from ensuring safe filtration to automatic operation.

Controlled brewing and fermentation

Control the brewhouse, fermentation, and supervise lagering.

Filling and washing of kegs

Have our system properly wash and fill your kegs to achieve the highest quality and stability.

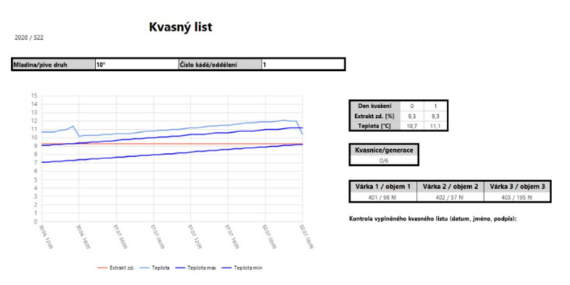

Complete archiving of production data, including reporting

Because moving your business forward is all about incremental improvement and streamlining, we have prepared a special ECS Archive module within the ESONIC Craft Brew platform. This powerful industrial history database collects large amounts of process data in real time, helping you improve quality, save money, and minimize risk.

Any data source

Add data from other devices, compare and evaluate.

Save energy

Track energy consumption in real time and find where you can be more energy efficient.

Clear archiving

Keep control of your data, including all the proper logs.

Advanced balance sheet

Have the system produce quality and quantity balance sheets, including batch production progress documentation.